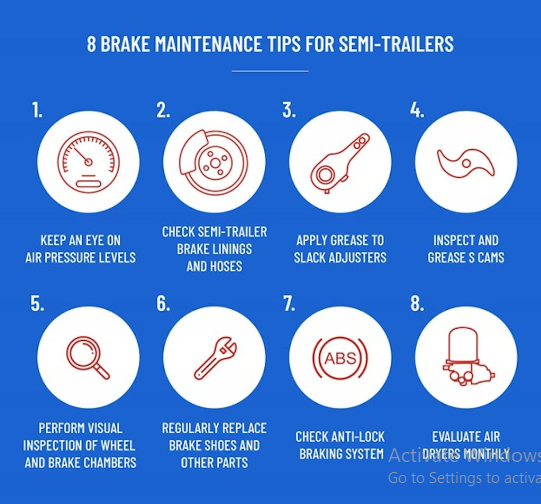

Regular inspection and prompt maintenance of automatic slack adjusters are essential for safe vehicle operation. Follow manufacturers’ guidelines and check for signs of wear to ensure proper brake function.

Maintaining a rigorous inspection regime for automatic slack adjusters is crucial to guarantee the safety and longevity of your vehicle’s braking system. These components, responsible for maintaining the necessary clearance between the brake drum and linings, can dramatically affect your vehicle’s stopping ability if not properly adjusted or if they malfunction.

A well-rounded introduction to slack adjuster maintenance must stress the importance of adhering to recommended service intervals, the need for immediate attention to any signs of excessive slack, and the use of proper tools and techniques during inspection and adjustment processes. Such attentiveness ensures compliance with safety standards and helps avert potential on-road failures, contributing to overall road safety and vehicle performance.

Regular Inspection

Regular inspection ensures the safety and longevity of automatic slack adjusters in heavy-duty vehicles. These components play a critical role in the brake system. Neglecting their maintenance can lead to poor brake performance. It may also cause dangerous situations on the road. This section offers essential tips for inspecting your automatic slack adjusters.

Visible Inspection

Initiate the process with a thorough visual check. Look for obvious signs of wear or damage. Spotting issues early can prevent costly repairs later. Pay close attention to the following details:

- Check for corrosion. Rust can compromise the adjuster’s integrity.

- Inspect the mounting. Ensure adjusters are secure and properly positioned.

- Observe the control arm. It should be at the correct angle to function properly.

- Examine the air chambers and push rods. They must be free from damage and have secure connections.

Functional Inspection

After a visual examination, proceed to a functional inspection. Test the slack adjusters to confirm they engage and release accurately:

- Apply the brake. Watch for smooth operation of the adjuster.

- Release the brake. The adjuster should return to its original position.

- Measure the stroke. Use a ruler to ensure it’s within the manufacturer’s recommendations.

- Listen for unusual sounds. Noises may indicate internal issues.

A functional test helps highlight hidden concerns. Regular checks can save time and ensure safety.

Maintenance Procedures

Keeping automatic slack adjusters in top condition requires regular maintenance. Proper care ensures safety and extends the life of your braking system. Let’s delve into the essential maintenance steps you should follow.

Cleaning And Lubrication

Regular cleaning and lubrication prevent build-up and wear. Follow these steps:

- Switch off the vehicle and apply wheel chocks.

- Wipe the adjuster with a clean cloth.

- Inspect for dirt, debris, or corrosion.

- Use brake cleaner spray, if needed.

- Lubricate moving parts with high-temperature grease.

Adjustment

To ensure brakes work well, check the adjustment:

- Lift the vehicle using proper equipment.

- Rotate the wheels and check for drag.

- Adjust the slack adjuster as per the manufacturer’s manual.

- Verify correct adjustment by rotating the wheel again.

Replacement Of Worn Parts

Inspect each component carefully.

Look for signs of damage or excessive wear:

- Check the adjuster arm, clevis pins, and bushings.

- Measure the pushrod stroke.

- Replace any part that doesn’t meet specifications.

Always use manufacturer-recommended parts for replacements.

Safety Guidelines For Inspection And Maintenance

A thorough safety inspection and maintenance routine for Automatic Slack Adjusters is crucial. Regular checks guarantee reliable brake performance. Follow these safety guidelines to ensure a secure and effective maintenance process.

Lockout/tagout Procedures

Before starting any inspection or maintenance, the lockout/tagout procedure is vital. This process ensures that vehicles are inoperable during servicing to prevent accidental movement. It involves turning off the vehicle, disconnecting the battery, and placing a lock or tag on the power sources to indicate the vehicle should not be used.

Proper Tools And Equipment

- Use the right tools for adjusting and repairing slack adjusters.

- Calibrated torque wrenches ensure accurate adjustments.

- Brake service kits might include specific adjuster tools for maintenance.

Personal Protective Equipment (ppe)

Personal safety is non-negotiable. Essential PPE includes:

Equipment | Use |

Safety glasses | Protect eyes from debris |

Gloves | Guard hands against cuts and burns |

Steel-toed boots | Shield feet from heavy objects |

Conclusion

Regular upkeep of automatic slack adjusters is crucial for road safety and vehicle performance. Ensuring they are properly inspected and maintained can prevent costly repairs and downtime. Remember, a well-adjusted brake system is the backbone of your vehicle’s safety protocol.

Stay informed, stay safe, and keep your journey smooth with these essential maintenance tips.

Related Article

Read Now

How Much Free Play Should You Expect in a Slack Adjuster? Maximize Performance!

The ideal amount of free play in a slack adjuster...

Read MoreRevolutionary Evolution: Historical Development of the Automatic Slack Adjuster

The automatic slack adjuster (ASA) has developed over time to...

Read MoreCustom Solutions for Automatic Slack Adjuster Systems: Boost Safety & Efficiency

Custom Solutions for Automatic Slack Adjuster Systems enhance braking consistency...

Read MoreAutomatic Slack Adjuster Warranty And Repair Information: Quick Guide

Automatic Slack Adjusters come with various warranty conditions, which typically...

Read More